Technical Articles

Birth of a Hole

Perforating Basics The Perforating Process Program Objectives Define Die Clearance Illustrate the Six Steps of the Perforating Process Explain the...

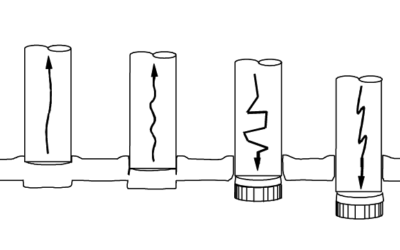

Shear Angles

Shear Angles can be applied to all punch points. These angles are used primarily to reduce slug pulling. Single and Double Shears can be used to...

Perforating Round Tubing

Perforating holes through one side of a round tube can present several unique problems for metal stampers. The most common are tube deformation,...

Tool Steels for Punch & Matrix Components

Selecting the proper Tool Steels, Heat Treatment, & Surface Treatments for a stamping application can be a complex and confusing process. To...

Die Clinic: Tooling

Like an iceberg, most of your die costs lurk below the surface. How many times has someone compromised quality or service for price? Die Clinic...

Productivity Selector

The Productivity Selector correlates different types of stock, grouped by tensile strength, type of clearance and the resultant burnish length and...

Tool Steels

Properties, Comparisons, & Benefits Choosing Tool Steels—Balancing Toughness, Wear Resistance, & Compressive Strength Tool steels refer to a...

Problem Solving Guide

Solutions for punch wear, breakage, and other problems come from both time-tested techniques (e.g., adding a larger-than-normal radius under the...

Protecting Your Punch Tool Investment

Economic shortcuts in the build process almost always add to production costs in the form of increased maintenance and production scrap. To avoid...