Providing Solutions to Make You More Profitable

Dayton Progress Understands that Stamping High Tensile Strength Steel Is Hard—Literally

- Low punch performance & cycle life

- Impact resistance

- Punch edge chipping, edge wear or breakage

- Stopping production to service or re-sharpen tooling

Ultimately you have more downtime and increased maintenance costs; robbing your company of profit.

You can rely on solutions from Dayton Progress to increase profits.

The Dayton Progress Solution

We have developed punches specially designed for stamping today’s high tensile strength steels. The combination of the right punch material, design, coating, and finish will improve your day-to-day operations.

Punch Design: Features that perforate cleanly and eject slugs efficiently.

Punch Material: Durable tool steel, heat treated in-house in our modern vacuum ovens.

Coatings: Dayton Progress uses long lasting coatings that reduce friction and increase wear life.

Finishes: Precision micro finishes that enhance the performance of our coatings.

Options That Fit Your Situation and Budget

| Production | Good | Better | Best | Callout |

| Punch Material | M2 | PS4 | PS4 | M2, PS4 |

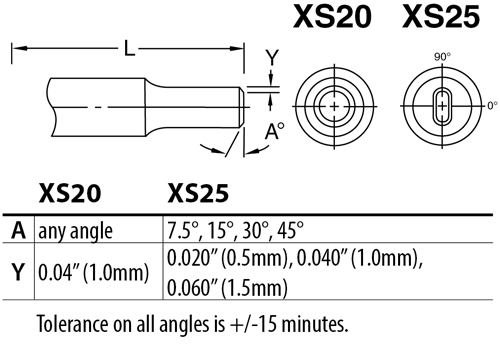

| Chamfer | — | Yes | Yes | XS20 (round) or XS25 (shape) |

| Jektole | — | Yes | Yes | BJ_, AJ_F, TJ_F |

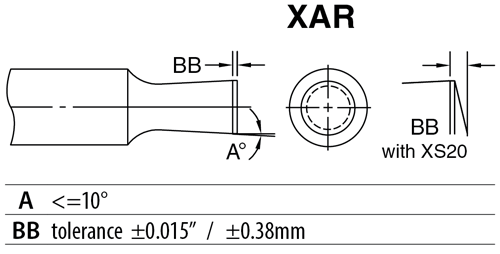

| Back Taper | — | — | Yes | XAR (round) |

| Coating | Yes | — | — | XAN |

Order Examples

| Good | VPX 37 1020 P.250 M2 XAN XS20 A7° | DPO 08 1371 P4.20 W3.5 M2 XAN XS25 A15° Y0.5 |

| Better | VJX 37 1020 P.250 PS4 XAN XS20 A5° | DJX 08 1371 P4.20 M2 XAN XS20 A5° |

| Best | VJX 37 1020 P.250 PS XAN XS20 A5° XAR | DJX 08 1371 P4.20 PS XAN XS20 A7° XAR |

Optimizing Punch Performance

| Chamfer Shear AnglesXS20, XS25—Shear Angles are used primarily to reduce slug pulling. This feature has been proven effective to generate longer cycle life.Studies show that the XS20 (round) and XS25 (shape) shear angle can improve life cycles by 200-300%. |

|

Jektole® Punch Many high tensile strength material applications require extreme lubrication throughout the die. The increased lubrication magnifies surface tension and increases the possibility of slug bonding. The benefits of using a Jektole punch are twofold. The spring loaded Jektole pin (extending from the face of the punch) is a method to retain the slug in the die button after perforating. The Jektole punch also has a side vent hole which allows air to get in, breaking the vacuum and lubrication seal between the punch and slug. Many high tensile strength material applications require extreme lubrication throughout the die. The increased lubrication magnifies surface tension and increases the possibility of slug bonding. The benefits of using a Jektole punch are twofold. The spring loaded Jektole pin (extending from the face of the punch) is a method to retain the slug in the die button after perforating. The Jektole punch also has a side vent hole which allows air to get in, breaking the vacuum and lubrication seal between the punch and slug. |

Back Taper XAR—Round punches can be ground with a back taper to reduce stripping pressure, heat, and material build up on point. This precise change in the size facilitates stripping material and is much less likely to adhere to the punch. Grind life is not affected. The reduction in diameter is so small that the punch remains within normal tolerances for both hole size and die clearance throughout its life. XAR—Round punches can be ground with a back taper to reduce stripping pressure, heat, and material build up on point. This precise change in the size facilitates stripping material and is much less likely to adhere to the punch. Grind life is not affected. The reduction in diameter is so small that the punch remains within normal tolerances for both hole size and die clearance throughout its life. |

|

High-Aluminum Coating XAN—This ultra-hard (harder than carbide), high-aluminum coating provides high temperature resistance. It is well-suited for applications where surface heat is generated. High tensile strength, dual phase, TRIP, and newer GIGA steels benefit from this coating.(Approximate hardness: Vickers 3400) XAN—This ultra-hard (harder than carbide), high-aluminum coating provides high temperature resistance. It is well-suited for applications where surface heat is generated. High tensile strength, dual phase, TRIP, and newer GIGA steels benefit from this coating.(Approximate hardness: Vickers 3400) |

Select the Coating that Matches Your Specific Needs

Dayton’s leading-edge coatings and other unique surface treatments have been developed to improve inplant performance by increasing tool hardness and wear resistance.